5 New Battery Technology for Electric Cars (in 2023)

The development of safe and efficient systems of energy storage is the trump card of the electric revolution. In this article, we will talk about 5 new battery technologies for electric cars and the next-gen battery technology that is set to revolutionize the electric vehicle industry. Some of these are going to be commercialized for mass EV adoption, and some will revolutionize everything, but need a little more time before they hit the market.

A number of problems arise when it comes to the use of today’s most widely used energy storage systems in transportation.

Current lithium-ion batteries have a relatively low energy density. This means that if we want to increase the distance covered by a vehicle on a single charge, the weight and volume of the battery will need to be increased significantly, which will deteriorate the performance and comfort of the vehicle, increasing the cost. Then just leave it alone.

These are the main factors why, for example, electric airplanes are currently out of use. Furthermore, lithium-ion batteries pose serious safety issues in the case of a hypothetical car accident due to the flammable liquid electrolytes.

Top 5 New Battery Technology for Electric Cars

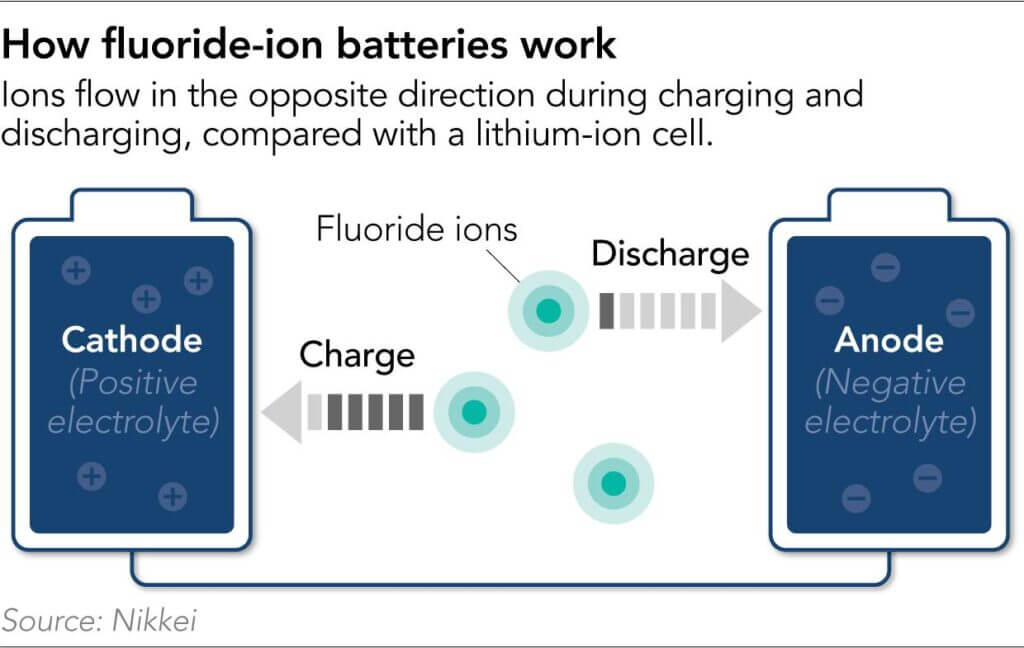

These issues can be overcome by the development of new systems for energy storage. One of the solutions in 5 New Battery Technologies for Electric Cars is the use of fluoride-ion batteries.

1. Fluoride ion batteries Technology

(offer 1200-1500 miles of range)

Fluoride ion batteries have a main working principle similar to that of Lithium-ion batteries. Ions shuttle between the cathode and anode in processes of charge and discharge, but in this case, negatively charged fluoride ions are used instead of lithium ions. Teams of researchers from Kyoto University and Toyota Motor have created a prototype of this kind of battery that can overcome the disadvantages of Lithium-ion batteries mentioned before.

Fluoride ion batteries have a main working principle similar to that of Lithium-ion batteries. Ions shuttle between the cathode and anode in processes of charge and discharge, but in this case, negatively charged fluoride ions are used instead of lithium ions. Teams of researchers from Kyoto University and Toyota Motor have created a prototype of this kind of battery that can overcome the disadvantages of Lithium-ion batteries mentioned before.

Fluoride ion Batteries Benefits

The first great advantage of this prototype is that the electrolyte is solid and inert, which means that this type of battery is less likely to catch fire in case of battery damage. The cathode in this battery consists of energy-dense copper, and the anode is composed of lanthanum fluoride. These materials are characterized by much larger fluoride ion capacities and higher reversibility compared to Lithium-ion batteries.

Researchers claim that the use of this system will enable affordable mass electric vehicles with lightweight batteries to run about 620 miles or 1000 kilometers on a single charge. The battery can potentially offer about three times higher energy density, which will bring the idea of electric airplanes to reality. Solid-state fluoride ion batteries are also more than three times cheaper than Lithium-ion batteries, offering a 30 price tag per kilowatt-hour.

On the other side of the coin, the used electrode materials are subjected to fast degradation, which results in a shorter battery lifespan. This may be one of the disadvantages of this prototype, although researchers claim they have found the solution to this problem by using a Cobalt-nickel-copper alloy. Another challenge is the high temperature required for the efficient functioning of its solid electrolyte. There have been some tests where the battery was successfully operated even at room temperature, but many experts believe it will take at least eight years before commercially viable fluoride ion batteries are available, which is a fairly normal period for bringing a novel battery solution from lab to production.

In parallel, researchers around the world are competing to create better Lithium-ion batteries with solid-state electrolytes, which will not only increase the safety of a battery cell but also the energy density compared to the current Lithium-ion batteries with liquid electrolytes. However, solid-state fluoride ion batteries can theoretically offer much better energy density, diminishing the weight of a vehicle by replacing the rigid structural car elements with batteries.

Structural Batteries

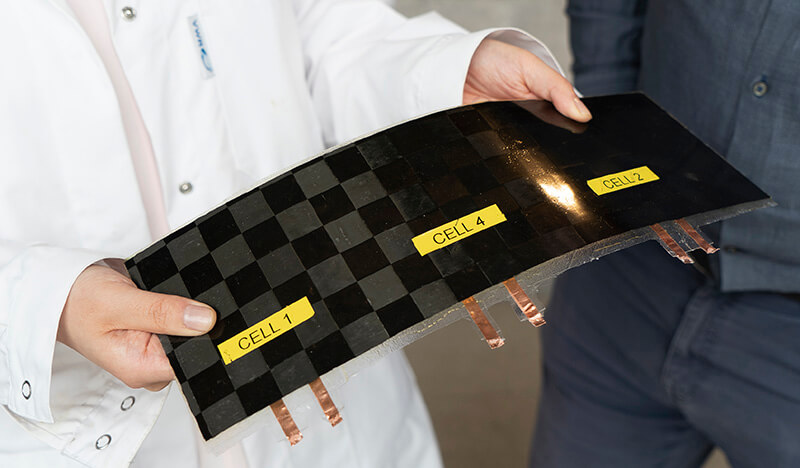

This would take care of two birds with one stone, simultaneously transforming a battery pack into a load-bearing structure. Such technology, named structural batteries, has already been adopted by Tesla to produce, for example, the new lightweight version of Model Y.

The Structural Battery project being developed by researchers at the Chalmers University of Technology aims to turn the body shell of a vehicle into a battery. The team has already created several structural battery prototypes and now wants to take the technology to the next level by depositing the active cathode material on carbon fiber, instead of the currently used aluminum foil. The anode is also made of carbon fiber and the separator is an ultra-thin fiberglass fabric. In this case, the inner parts of the battery, such as the current collectors and the separators, have load-bearing functions. The carbon fiber is as strong as aluminum, but much lighter, allowing for designing a structural battery with both rigidity and better energy storage capacity than the current best prototype.

Read More:

Despite still having a few times less energy density than the current oxide-based Lithium-ion batteries, this technology greatly reduces the weight of a vehicle by utilizing the chassis as a battery. This advancement allows for thin and even flexible structural batteries, and the possible applications of these new multi-functional systems are only limited by our imagination.

As the research leader says, the Next Generation structural battery has fantastic potential. If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops, or electric bicycles that weigh half as much as today and are much more compact.

The biggest challenge of this kind of structural battery will be its flammability, as it uses organic electrolytes like common batteries. Hence, the development of solid-state electrolytes would bolster the commercialization of structural batteries. Besides, there is a potential to extend the range of an aerial vehicle by over 50 percent when displacing the wing panels with structural energy-storing elements. This will significantly reduce the glamorous requirements for the gravimetric capacity of electric aviation batteries.

2. Structural Battery- Massless battery by Chalmers University

The Structural Battery project being developed by researchers at the Chalmers University of Technology aims to turn the body shell of a vehicle into a battery. The team has already created several structural battery prototypes and now wants to take the technology to the next level by depositing the active cathode material on carbon fiber, instead of the currently used aluminum foil. The anode is also made of carbon fiber and the separator is an ultra-thin fiberglass fabric.

The Structural Battery project being developed by researchers at the Chalmers University of Technology aims to turn the body shell of a vehicle into a battery. The team has already created several structural battery prototypes and now wants to take the technology to the next level by depositing the active cathode material on carbon fiber, instead of the currently used aluminum foil. The anode is also made of carbon fiber and the separator is an ultra-thin fiberglass fabric.

In this case, the inner parts of the battery, such as the current collectors and the separators, have load-bearing functions. The carbon fiber is as strong as aluminum, but much lighter, allowing for designing a structural battery with both rigidity and better energy storage capacity than the current best prototype.

Despite still having a few times less energy density than the current oxide-based Lithium-ion batteries, this technology greatly reduces the weight of a vehicle by utilizing the chassis as a battery. This advancement allows for thin and even flexible structural batteries, and the possible applications of these new multi-functional systems are only limited by our imagination. As the research leader says, the Next Generation structural battery has fantastic potential. If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops, or electric bicycles that weigh half as much as today and are much more compact.

The biggest challenge of this kind of structural battery will be its flammability, as it uses organic electrolytes like common batteries. Hence, the development of solid-state electrolytes would bolster the commercialization of structural batteries. Besides, there is a potential to extend the range of an aerial vehicle by over 50 percent when displacing the wing panels with structural energy-storing elements. This will significantly reduce the glamorous requirements for the gravimetric capacity of electric aviation batteries.

3. Bodyshell as energy storage By Lamborghini and MIT

Another amazing massless energy storage project has been introduced as a result of the collaboration between Lamborghini and MIT. The ultimate goal of the team is to turn the next-gen concept car, dubbed Terzo Millennio, into an accumulator for energy storage. The technology can allow for monitoring the car’s carbon fiber structure. If tiny cracks should appear, for example, due to a minor impact or just simple material fatigue, the charge can traverse through the car’s body and kick-start a self-repairing process to prevent the cracks from growing.

Another amazing massless energy storage project has been introduced as a result of the collaboration between Lamborghini and MIT. The ultimate goal of the team is to turn the next-gen concept car, dubbed Terzo Millennio, into an accumulator for energy storage. The technology can allow for monitoring the car’s carbon fiber structure. If tiny cracks should appear, for example, due to a minor impact or just simple material fatigue, the charge can traverse through the car’s body and kick-start a self-repairing process to prevent the cracks from growing.

An appetite for the transition from ICE-powered vehicles to EVs challenges the lithium-ion battery industry with a production of an enormous amount of battery cells. But lithium reserves are mainly concentrated in a few countries, and accelerating battery-grade lithium production is remarkably time-intensive. This makes companies delay some of their EV projects due to battery cell supply constraints.

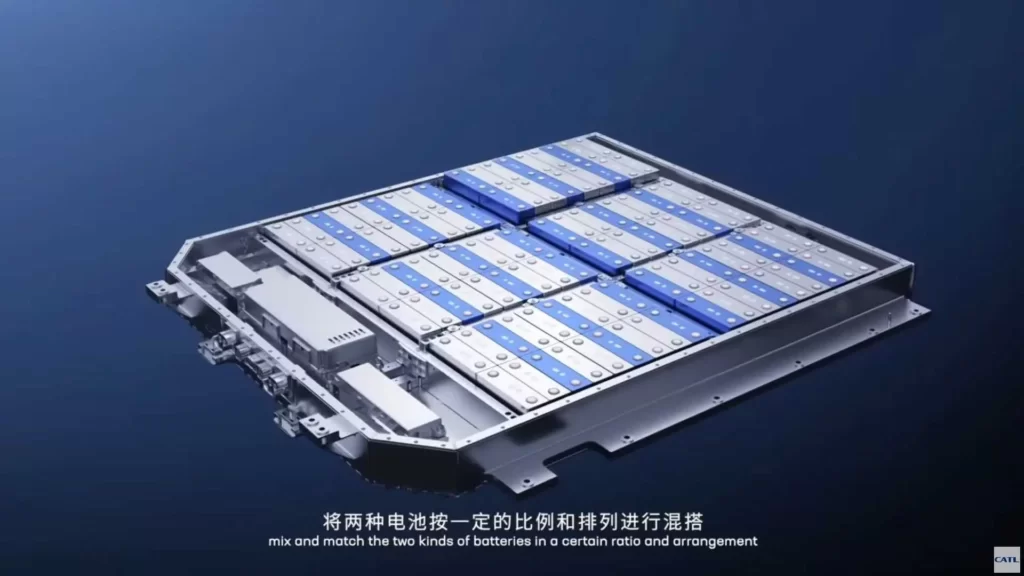

4. Sodium-ion battery By CATL (Na-ion battery)

The world’s biggest lithium-ion battery manufacturer, CATL, has announced the production of a sodium-ion battery in 2023. The working principle of the sodium-ion battery is similar to that of the lithium-ion battery, but with the charge stored by sodium ions, which are much more abundant on Earth and widely distributed all over the world compared to lithium. Due to the different properties between sodium and lithium, the cathode materials of the sodium-ion battery are a bit different.

The world’s biggest lithium-ion battery manufacturer, CATL, has announced the production of a sodium-ion battery in 2023. The working principle of the sodium-ion battery is similar to that of the lithium-ion battery, but with the charge stored by sodium ions, which are much more abundant on Earth and widely distributed all over the world compared to lithium. Due to the different properties between sodium and lithium, the cathode materials of the sodium-ion battery are a bit different.

CATL’s first-generation sodium-ion batteries

CATL uses a cheap Prussian white instead of lithium oxides or phosphates for the cathode material. For the anode, the company uses a hard carbon material similar to the carbon-based graphite anode in a lithium-ion battery, but further improvement can be achieved by adding silicon or silicon oxide. The theoretical capacity of the hard carbon depends on many more factors due to a different storage mechanism, and it can be higher than for graphite in lithium-ion batteries.

CATL: Battery Chemistry

CATL’s sodium-ion battery offers fast charging performance, allowing the battery to regain 80% charge in 15 minutes at room temperature. It also offers a capacity retention rate of more than 90% in a low-temperature environment of minus 20 degrees Celsius, while challenging many contemporary lithium-ion batteries in these regards. However, it has a major drawback of low energy density compared to oxide-based lithium-ion batteries. Currently, CATL’s first-generation sodium-ion batteries can achieve a capacity of 160 watt-hours per kilogram, similar to lithium-iron-phosphate batteries, which are used in standard-range Tesla Model 3s.

Thanks to their abundance, sodium-ion batteries can scale up the production of small EVs offering cheaper price tags and all the aforementioned advantages. The high interest in sodium-ion batteries stimulates an active search for new electrode materials with superior properties.

For example, recently discovered Vanadium pyrophosphate is a promising candidate because of its high thermal stability, which solves safety issues and helps get rid of an advanced thermal regulation system that generally takes additional volume and impacts EV range. Vanadium pyrophosphate may also serve as both cathode and anode material, which will further enhance safety and provide long battery life while keeping a similar high voltage. A flame retardant electrolyte is the last piece of fireproof batteries.

While scientists focus on sodium-ion batteries, we should not forget about lithium-ion batteries. They have already shown their potential in portable equipment and electric vehicles. One option to increase the energy density of a lithium-ion battery is to enrich it with nickel and add silicon to the graphite anode.

However, these chemistry innovations are prone to fast degradation and have even more serious safety issues. Gradual improvements have opened an avenue for producing 600-mile range EVs in 2022.

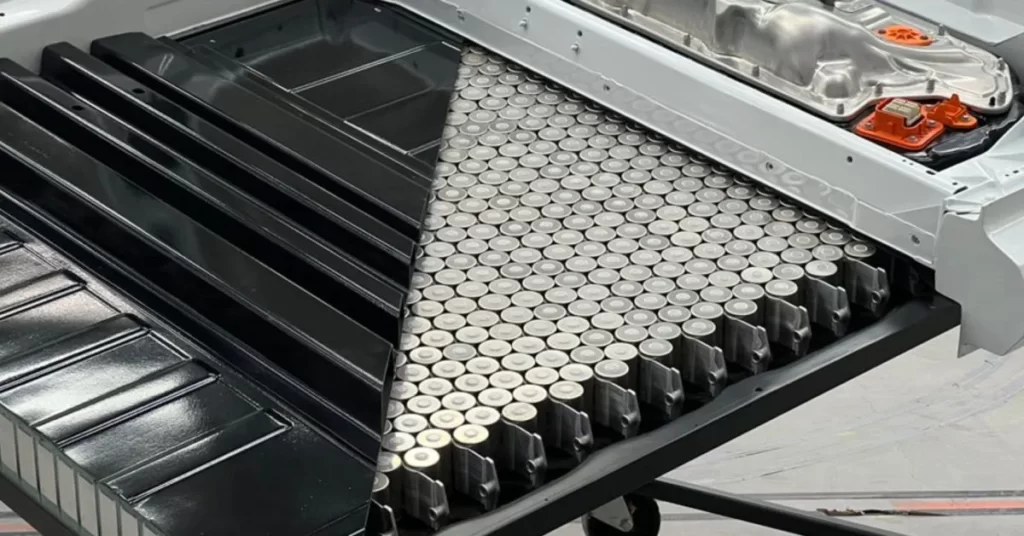

Dalhousie University, the research partner of Tesla, is focusing its efforts on mid-range batteries based on unfashionable NMC-532 cells constructed with only sufficient graphite without silicon. It has already been shown that the layodoxide composition of an NMC-532 cell when nickel is 50, manganese is 30, and cobalt is 20, can maintain more than 90% of its initial capacity up to 1 million miles of operation.

In 2019, the media called this battery the “million-mile battery,” which featured micron-scale individual single crystalline NMC particles. Such a format limits the typical degradation processes such as particle cracking in addition to surface reactivity.

The researchers continued experimenting and during one of the tests, they charged the NMC only to half of its full capacity while draining the graphite entirely. This led to smaller changes in the cathode’s crystal structure and caused even fewer cracking and side reactions. This three-year research after the “million-mile battery,” which can be assumed as a 20-year but resulted in the 100 Year battery.

5. 100 Year or 4-mln mile battery By Jeff Dahn & Tesla Representing

The 100-year or 4-million-mile battery, represented by Jeff Dahn and Tesla, is called the Sentry battery. It is achievable due to the use of Li FSI electrolyte, which is balanced and operated at 3.8 volts, while offering better energy density than LFP cells powering the Tesla Model 3.

The 100-year or 4-million-mile battery, represented by Jeff Dahn and Tesla, is called the Sentry battery. It is achievable due to the use of Li FSI electrolyte, which is balanced and operated at 3.8 volts, while offering better energy density than LFP cells powering the Tesla Model 3.

Could you imagine that the battery life might exceed a regular human life?

First of all, this technology is required for the long-term Tesla strategic vision. Its autopilot will eventually open the door to autonomous driving, and this battery can be used to power Tesla’s Robo taxi network. Moreover, such a long life cycle makes economically beneficial vehicle-to-grid services when the car is connected to the electric grid when parked.

Eventually, the energy-storing capability of electric vehicles will solve the major problem of renewable power, while allowing EV owners to sell the extra energy to companies in order to balance variations in energy production and consumption. So your electric car can also generate money for you when it’s parked while helping the economy reach carbon neutrality.

As we can see, carbon neutrality has become a global consensus, and more and more research groups are working on developing an efficient green energy source for our future energy system. The ideas that could become reality because of these top 5 new battery technologies for electric cars are only limited by our imagination. What do you think are the most revolutionary technologies that could be possible due to the commercialization of next-generation batteries?